Piston Jaw Increases Vise Flexibility, Productivity

Up until now, the ability to use standard machine vises to securely hold multiple parts for increased machining production has been limited to designed costly dedicated fixturing--a solution that sacrifices flexibility, versatility, and ultimately, profitability.

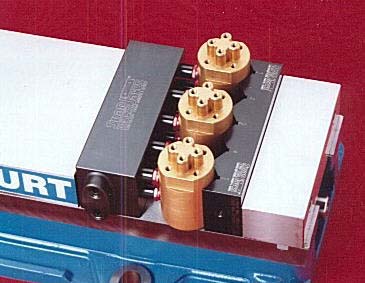

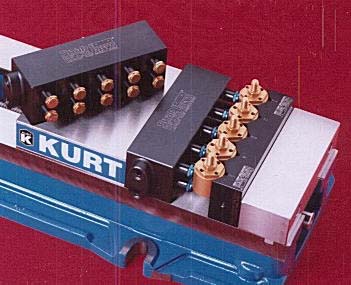

The Piston Jaw vise jaw from Snap Jaws Manufacturing (Troy, MI) can provide a solution for multiple part holding requirements. It features a patent-pending hydraulic design that uses a series of internal passages and O-ring sealed pistons to provide rigid holding of up to five parts at a time for multiple-part machining.

The key to the jaw's utility is its ability to hold similar parts with different outside dimensions (up to 0.025 in.) with equal and adequate holding force. The jaw is designed to be used with a standard 6-in. milling vise, so part size limits the number of parts that can be held in one setup.

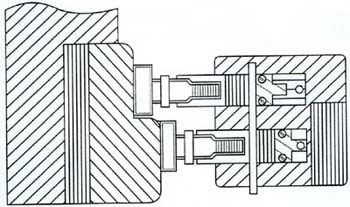

The basic design features two rows of clamping pistons built into a 2-in. wide by 6-in. long self-contained sealed steel housing. The housing is machined with internal hydraulic oil passages positioned behind the pistons to provide the consistent and uniform clamping pressure. There are five pistons in each row spaced at a centerline distance of 0.750 in. above and below each other. Side-to-side centerline spacing is 1.200 in.

Secondary oil passages connect the first chamber in the top row with a second chamber in the bottom row so the flow of hydraulic fluid between the rows is proportionally restricted to provide uniform holding force. The pistons independently compensate with the hydraulic fluid pressure equalizing and balancing the force for each piston. The assembly also uses a pin, inserted through the housing and slots in each upper and lower pair of pistons, to mechanically prevent the pistons from being forced out of the housing when clamping pressure is applied to the other pistons.

The Piston Jaw can be used with a matching V-jaw to hold one to five parts ranging from 3/8 to 1-3/16 in. diam or three parts up to 2 in. diam using every other V position. With machined soft jaws, the system can securely hold even hex, rectangular or irregularly shaped parts.

The Piston Jaw features a quick-change vise design and is available with a variety of interchangeable piston tips that include steel, aluminum, brass, carbide, serrations, stainless steel, nylon, or machinable steel. A special swivel tip is also available.

Snap Jaws Manufacturing, 33215 Dequindre, Troy, MI 48083. Phone (248) 588-1099.