A Revolutionary New End Mill From Union Tool That Cuts Cemented Carbide

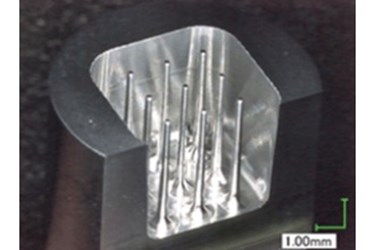

A new patented UDC diamond coating introduced by Union Tool Europe of Neuchatel, Switzerland, is reported to enable carbide end mills to physically cut shapes and features in cemented carbide work material such as the micro needles shown in Figure.

Union Tool Europe, a wholly owned subsidiary of Union Tool Co in Japan, states that by combining optimised cutting geometry with the UDC coating users can apply direct milling strategies and so remove the need for grinding or using EDM techniques to form complex 3D carbide shapes. This direct milling process allows for an unlimited range of features (especially microscale ones) to be milled in cemented carbide that are not otherwise possible by grinding or by EDM techniques.

The highly efficient and durable UDC coating is said to have a hardness 9,000 HV, which is very similar to single crystal diamond, and its extreme wear resistance also gives a class leading surface finish, enabling the end mill to produce finished parts without pits or burrs. Production time can be up to 80% quicker compared with EDM or grinding.

A case study using a single Ø2.00mm UDC coated carbide ball end mill to both rough and finish a Ø9.00 star-shaped 3D feature in VF-20 Super Micro Grain carbide (92.5Hra) took just 39 minutes, which previously may have taken up to 4 hours.

For more information, visit www.uniontool.com.

Source: Union Tool Europe